Optimum Spare Parts Inventory Control With Installed Base Information In Existence of Secondary Markets

(Funded by Tübitak)In spare parts supply chain, demand heavily depends on the size of the installed base as spare parts are one of the main ingredients of maintenance activities. Therefore, original equipment manufacturers (OEMs) try to track the number of capital products in use and their usage rates. This information is utilized in several studies by different researchers for spare parts inventory control (Pinçe and Dekker, 2011; Dekker et al., 2013). It is shown that considering the number of capital products for spare parts inventory control helps reducing holding and purchasing costs of spare parts inventory. With the advancement of internet, electronic market places are being widely used by many companies for busines-to-business (B2B) exchanges of products and services. In spare parts supply chains, increasing amount of maintenance companies use those internet platforms as they are usually cheaper and faster than the regular supplier of spare parts. Since traders on these electronic market places only sell their existing inventory, which they buy from another parties, most of the time these second hand parts are cheaper and also they are delivered fast (no production time is requiered). Such marketplaces are referred to as secondary (or gray) markets in the literature. For a company, who provides maintenance service to capital products, secondary markets not only are sources of spare parts, but also they are used to sell excess inventory to reduce holding cost and increase liquidity. In a different business context recent studies show that the existence of secondary markets allows retailers to buy in large quantities from their suppliers and to enjoy quantity discounts while selling the excess inventory if necessary. Hence, in many sectors retailers greatly benefit from trading with secondary markets. However, this phenomenon has never been addressed for spare parts supply chains which are different due to erratic and intermittent nature of demand and installed base dependency. Furthermore, the optimal purchasing policy in existence of secondary markets is also unknown for spare parts supply chains. From inventory sourcing point of view, buying from secondary markets is advantageous for maintenance companies as they are cheaper and faster compared to the original supplier. On the other hand, the amount of spare parts is limited on secondary markets and this amount varies over time due to the fact that other companies and even customers have access to traders and brokers on secondary markets. Hence, secondary markets are not long-term reliable supply sources for maintenance companies and it is necessary to consider them and regular supplier at the same time. This problem has a different setup than the previous dual sourcing studies in the literature (e.g. Veeraraghavan and Scheller-Wolf, 2008). In the classical dual sourcing setup, the main trade-off is between lead time and price. Specifically, one of the two suppliers is located close but it costs high whereas the second supplier is far, i.e. longer lead time, but its cost is lower. This classic problem setting is not useful in our problem since the supply source with shorter lead time is also chaper (secondary markets). The closest study to such a problem setting is given by Hekimoğlu (2015) who only considers a stationary demand distribution.

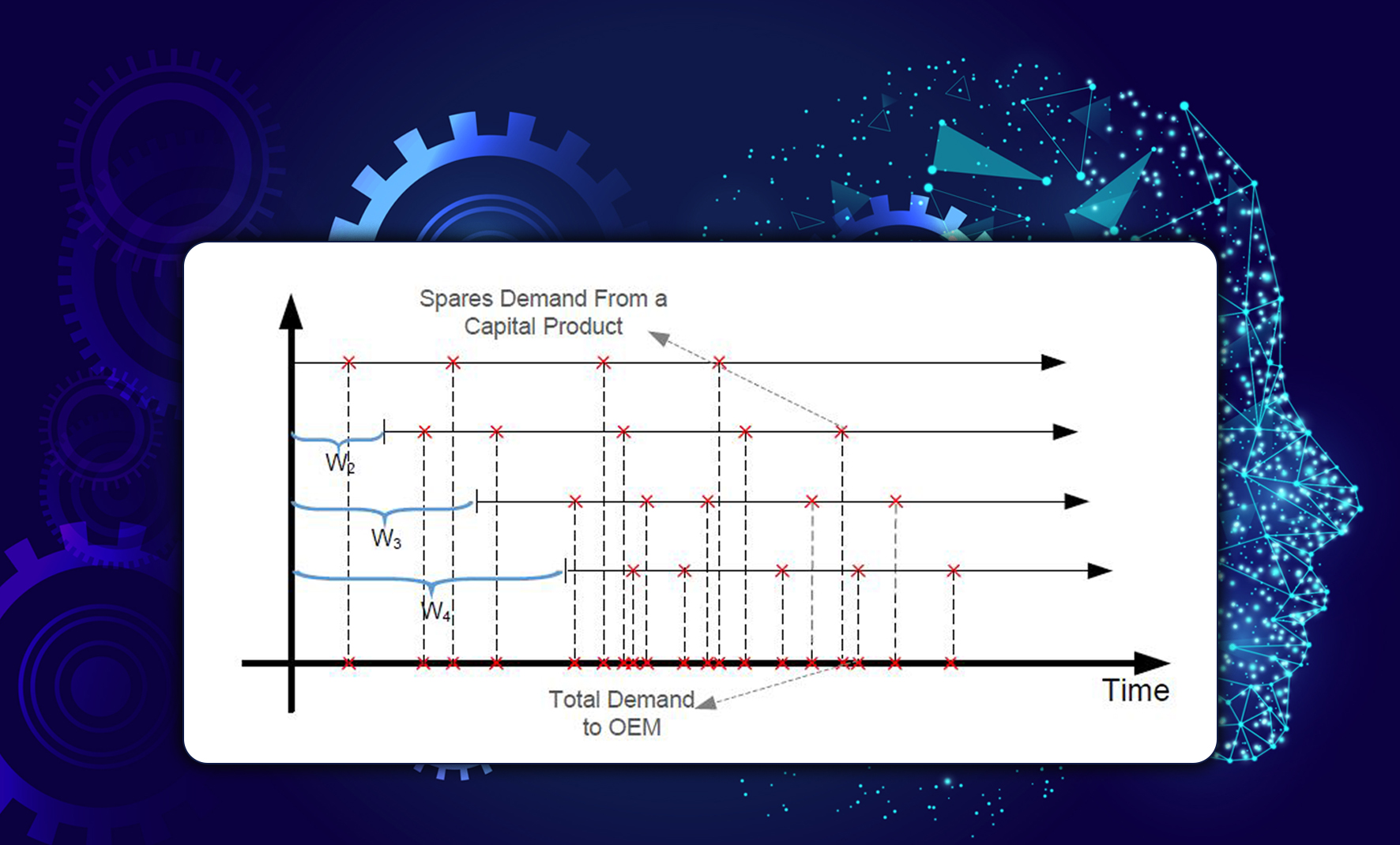

In this project, it is aimed to address the study the optimal purchasing policy in existence of secondary markets and a regular supplier. Secondary markets will be considered as a cheap and fast supplier with random capacity whereas the regular supplier has no capacity but it is more expensive and it delivers with a longer lead time. In a multi-period setting, it is aimed to obtain an analytic characterization of the inventory control policy. Later, we will develop an algorithm that can optimize parameters of the control policy in a polynomial time. In the demand side, we consider installed base dependency of spare parts. Therefore, the demand distribution will be assumed to be nonstationary as the size of installed base changes in different phases of the life cycle of a capital product. For instance in the introduction phase, new capital products are sold by the OEM and the size of the installed base gets larger. Conversely in the final phase, called out-of-product or end-of-life, the installed base shrinks which causes decreasing spare parts demand. The output of this project will shed light on the problem of spare parts inventory control in existence of secondary markets with varying size of installed base.

From the methodological point of view, demand-side dynamics will be considered in two different scenarios. First, (stochastically) growing installed base will be considered. Under specific assumptions, analytic formulations for the first three moments of the nonstationary total spare parts demand will be developed. In the second scenario, declining size of capital products will be evaluated. Using a probabilistic analysis, moments of stochastically decreasing demand rate will be analyzed. To apply this nonstationary demand to a multi-period, periodic-review inventory control model, an approach based on the moments of nonstationary demand will be developed. Later, multi-period cost function will be analyzed for acquisition, holding and backlog costs using a recursive dynamic programming formulation. This model will be subject to mathematical analysis in order to understand its characteristics and the optimum policy. Once the optimum policy is established, the second milestone is developing an algorithm that gives the optimal policy parameter (possible for a given service level constraint). Hence the output of the project will be a comprehensive solution to the problem of dual sourcing from secondary markets and a regular supplier when the demand is dependent on the size of the installed base.

Orginality of the proposed work mainly comes from the novelty of using installed base information in dual sourcing setting which is strictly different than the classical problem setting as explained above. In addition, we will explore the dependency between the number of items on secondary markets and the size of installed base. Specifically, the number of spare parts on secondary markets change in different phases of the life cycle of a capital product. In the introduction phase, there is no spare parts on the secondary market as majority of spare parts stems from sales of excess inventory by different maintenance companies. On the other hand, there is a vast amount of spare parts on secondary markets in the final phase of capital products’ life cycles. This negative correlation between the demand rate and the spare parts availability on secondary markets is exacerbated by cannibalization of old capital products and this feature constitutes another novel part of this project.

To sum up, in this project we aim to develop a solution to the problem of sourcing from secondary markets and a regular supplier by considering installed base information for the demand model. This study will fill a research gap in the literature as this problem has never been addressed before.

Expected project outputs can be listed as follows:

- A demand model for spare parts of stochastically growing or declining installed bases,

- A mathematical model for a dual sourcing problem including secondary market dynamics and nonstationary demand,

- The optimal policy (and an algorithm for its parameter optimization) for minimization of holding, backlog and acquisition costs of spare parts for the multi-period problem,

- A new heuristic for the solution, if necessary. Also analytic characterization of all heuristics’ performances that can be aplied to the problem.

Yedek Parça Envanter Yönetiminde Kurulu Sistem Bilgisinin Varlığında İkincil Marketlerin Optimum Şekilde Kullanılması

(Tübitak Projesi)Yedek parça tedarik zincirlerinde, talep müşteri tarafında kullanımda olan sermaye malı sayısına (kurulu sistem büyüklüğüne) yoğun bir bağımlılık göstermektedir. Bu nedenle sermaye malının üreticileri (Orijinal Ekipman Üreticileri, OEÜ) kullanılan sermaye malı sayısını ve kullanım oranlarını yakından takip etmektedirler. Özellikle bilgi teknolojilerinin daha da yaygınlaşması ile OEÜ’ler müşterilerindeki sermaye mallarınındaki değişiklere adapte olabilen envanter yönetim politikalarını uygulayabilir hale gelmişlerdir. Kurulu sistem bilgisi literatürdeki bazı çalışmalarda envanter kontrol yöntemi için girdi olarak kullanılmış ve bu bilgiyi kullanmanın satın alma ve envanter tutma maliyetini azalttığı gösterilmiştir.

İnternetin yaygın kullanımı ile beraber, işten işe (B2B) ürün ve servis ticaretini elektronik platformlar önem kazanmaya başlamıştır. Yedek parça tedarik zincirlerinde, giderek artan sayıda bakım firması yedek parça tedariğinde ucuz ve hızlı oldukları için elektronik ticaret platformlarını kullanmaya başlamışlardır. Elektronik ticaret platformlarındaki tüccar ve aracılar, genelde ellerindeki ikinci el envanteri, orijinal tedarikçisinden daha ucuza satmaktadırlar. Ayrıca üretim için zamana ihtiyaçları olmadığından, elektronik platformlardaki tedarikçiler genelde daha hızlı bir şekilde teslimat gerçekleştirmektedir. Bu tür elektronik platformlara literatürde ikincil (veya gri) marketler denilmektedir. Sermaye mallarına bakım hizmeti veren bir firma için ikincil pazarlar ucuz ve hızlı bir tedarik kaynağı olmanın yanında, ellerindeki fazla envanteri de satarak likite çevirebildikleri ortamlardır. Başka bir sektör baz alınarak yapılan bir çalışmada, perakendecilerin tedarikçilerden yüksek miktarda alıp miktar iskontolarından yararlanırken, daha sonra da ellerindeki fazla envanteri satarak stok maliyetinden kurtulabildiklerini; bu nedenle de ikincil marketlerin varlığından yarar sağladıkları gösterilmiştir. Ancak bu fenomen, yedek parça tedarik zincirleri için daha önce hiç çalışılmamıştır. Dahası ikincil marketlerin varlığında bakım şirketlerinin optimum envanter kontrol politikası da literatürde konu ile ilgili açıklardan bir tanesidir.

Bakım şirketlerinin envanter yönetimi açısından ikincil marketlerden alım yapmak, daha ucuz ve daha hızlı oldukları için avantajlı bir seçenektir. Diğer taraftan ikincil marketlerdeki yedek parça sayısı sınırlıdır ve zaman içinde rassal bir şekilde değişmektedir. Bu rassal değişikliklerin temel nedeni, ikincil marketlerin bir çok farklı aktörün etkileşiminden oluşmasıdır. Bakım şirketlerinin tedarik kaynağı olarak satın alınabilecek parçanın rassal değişkenlikler göstermesi, ikincil marketlerin güvenilir bir kaynak olarak kullanılmasını engeller. Dolayısıyla bu şirketler, ikincil marketleri orijinal tedarikçileri ile eş zamanlı olarak değerlendirirler. Buna iki kaynaklı envanter tedariği adı verilmiştir.

İki kaynaklı envanter tedariği problemleri literatürdeki önceki çalışmalarda bulunmaktadır (örn: Veeraraghavan ve Scheller-Wolf, 2008). Klasik iki kaynaklı tedarik probleminde optimizasyon tedarik süresi ile fiyat arasında gerçekleşmektedir. Öyle ki iki tedarikçiden biri yakında yer almaktadır (kısa tedarik süresi) ancak pahalıdır. İkinci tedarikçi ise daha uzakta konumlanmış olup (uzun tedarik süresi) daha ucuzdur. Bu klasik problem yapısı yakındaki tedarikçinin (ikincil marketler) daha ucuz ancak kapasitesinin rassal olması nedeniyle bu projede önerilen problem yapısına uygun değildir. Önerilen proje yapısına en uygun çalışma Hekimoğlu (2015) tarafından talep dağılımının durağan olduğu varsayımı altında yapılmıştır. Ancak yedek parça tedarik zincirleri için bu varsayımın sorunlu olduğu yukarıdaki tartışmalar ışığında açıkça görülebilir durumdadır.

Bu projenin amacı ikincil marketlerin ve bir orjinal tedarikçinin varlığı altında optimal satın alma politkasının analitik karakterizasyonunun gerçekleştirilmesidir. İkincil marketler ucuz ve hızlı olmalarının yanında satın alınabilecek maksimum parçanın rassal olması nedeniyle güvenilmezdir. Diğer yandan orjinal tedarikçi yavaş ve pahalı olup sınırsız kapasiteye sahiptir. Çok periyotlu plan ufkunda, envanter kontrol politikasının analitik karakterizasyonun elde edilmesi projenin birincil amacını oluşturmaktadır. Daha sonra politika parametrelerini optimize eden bir algoritmanın geliştirilmesine çalışılacaktır. Modelin talep tarafında ise yedek parça talebinin kurulu sistemlerle olan bağımlılığı dikkate alınacaktır. Dolayısıyla talep dağılımı durağan olmayan bir yapıda ele alınacaktır. Metodolojik olarak talep tarafı dinamikleri için iki farklı senaryo dikkate alınacaktır. İlk olarak kurulu sistemlerin zamanla arttığı bir senaryo değerlendirilecek ve bu senaryodaki talep modeli yenileme teorisi kullanılarak geliştirilecektir. Sermaye malının satışları arası zamanın belirli bir dağılımından geldiği varsayılarak belirli bir zamandaki toplam yedek parça talebinin ilk üç momenti hesaplanacaktır. İkinci olarak ise kurulu sistem sayısının zamanla azaldığı bir senaryo dikkate alınacaktır. Kurulu sistemlerin devreden çıkışları arası zamanın rassal olduğu varsayımı altında sistemde oluşacak toplam yedek parça talebinin ilk üç momenti için analitik formülasyon geliştirilecektir. Talep için geliştirilen modellerin envanterin periyodik olarak kontrol edildiği bir optimizasyon sistemine uygulanabilmesi için herhangi bir periyottaki talep dağılımının momentlerini kullanan bir yaklaşım geliştirilecektir. Bu yaklaşımın kalitesinin ölçülmesi için yedek parçanın dağılımının nümerik yöntemlerle veya benzetim modelleri ile hesaplanması planlanmaktadır.

Takiben çok periyotlu bir planlama ufku için satın alma, stokta tutma ve yok satma maliyetlerini minimize eden rekürsif bir matematiksel model kurulacaktır. Bu matematiksel modelin analizi ile optimum kontrol politikasının karakterizasyonu gerçekleştirilecektir. Politikanın karakterizasyonundan sonraki aşama optimum politika parametrelerini veren bir algoritmanın kurulmasıdır. Bu aşamalar tamamlandığında ikincil marketlerin varlığında ve kurulu sistemlerin talep dağılımını belirlediği sistemler için uygulanabilir bir politika ve parametre optimizasyon algoritması proje çıktısı olarak elde edilecektir. Optimum politikanın analitik karakterizasyonunun mümkün olmadığı durumlarda yeni sezgisellerin geliştirilmesi veya literatürdeki metotların önerilen problem için performanslarının analizi için çalışılacaktır.

Önerilenen projenin özgün değeri temel olarak kurulu sistem bilgisinin iki kaynaklı tedarik probleminde kullanılmasından gelmektedir. Buna ek olarak, ikincil marketlerdeki parça sayısı ile kurulu sistem büyüklüğü arasındaki ilişkinin analizi de projenin diğer özgün değerini oluşturmaktadır. Öyle ki, ikincil marketlerdeki parça sayısı sermaye ürününün farklı yaşam döngülerinde farklılık göstermektedir. Örnek olarak sermaye malı yaşam döngüsünün büyüme aşamasındayken hem talep düşüktür, hem de ikincil marketlerde yedek parça bulunmamaktadır. Buna karşın, yaşamının son aşamasındaki sermaye malları için yedek parça talebi hızlıca azalırken, ikincil marketlerdeki yedek parça sayısı genel olarak yüksektir ve de bazı durumlarda zaman içinde artmaktadır. İkincil marketlerdeki parça sayısı ile toplam yedek parça talebi oranı arasındaki negatif korelasyonun modele dahil edilmesi bu projenin bir başka özgün tarafını oluşturmaktadır.

Projeden beklenen çıktılar şunlardır:

- Büyüme ve azalma dönemindeki kurulu sistemler için (değişken dağılımlı) toplam yedek parça talep modeli,

- Değişken talep dağılımı altında normal tedarikçiyi ve ikincil marketlerdeki değişkenliği dikkate alan bir envanter kontrol modeli,

- Yedek parçaların elde tutma ve yok satma (borçlanma) kaynaklı maliyetlerini minimize edecek bir kontrol politikası ve politika parametreleri için bir optimizasyon algoritması,

- Gerekli görüldüğü takdirde probleme uygulanabilecek sezgisellerin geliştirilmesi ve var olanlarla birlikte tüm sezgisellerin performanslarının matematiksel analizi.